Concentração de cerveja e bebidas

As soluções da Alfa Laval para concentração de cerveja e bebidas removem a água da cerveja, do vinho e da sidra após a fermentação. O uso de um processo de osmose reversa de alta pressão e baixa temperatura produz um concentrado de alta qualidade. O concentrado de bebida, uma vez reidratado para venda posterior, tem o mesmo sabor, aroma e teor de álcool do produto original. Uma cadeia de suprimentos baseada em concentrado reduz os custos de embalagem e transporte e o impacto ambiental.

Reduza seus custos de logística e melhore seu perfil de sustentabilidade com concentrados de cerveja e bebidas de alta qualidade

- Custos de transporte reduzidos devido aos volumes de transporte reduzidos com concentrados de cerveja e bebidas

- Custos gerais da cadeia de suprimentos mais baixos devido aos volumes reduzidos para embalar, armazenar e transportar

- Requisitos reduzidos de armazenamento no ponto de venda, como bares e restaurantes

- Após a reidratação do concentrado, a cerveja tem o mesmo sabor, aroma e teor de álcool do produto original

Obtenha soluções completas para suas necessidades de concentração de bebidas com os sistemas de concentração de cerveja e bebidas da Alfa Laval. Essas soluções compactas, confiáveis e com baixo consumo de energia aumentam a eficiência de produção, transporte, armazenamento e distribuição nas instalações de embalagem a granel e no ponto de venda. Isso se traduz em maior produtividade e rendimento, custos de capital mais baixos e distribuição mais sustentável.

Reduza os custos de transporte a granel em até 80% enquanto reduz a pegada de carbono de sua cadeia de suprimentos com os sistemas de concentração de cerveja e bebidas da Alfa Laval.

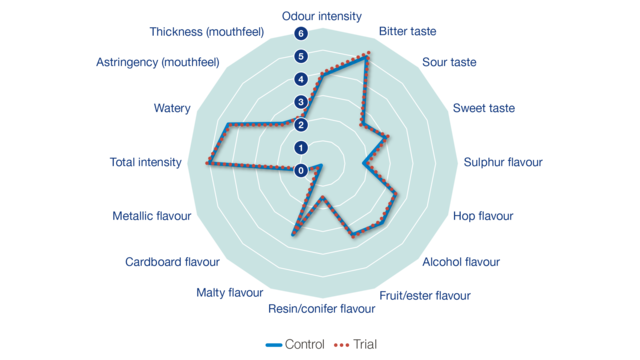

Sensory example: freshly reconstituted

Comparison of fresh beer and reconstituted Revos beer concentrate

Procedure

- Fresh reconstituted lager was subjected to detailed descriptive sensory panel testing

- Scores were averaged over a large group of panellists

Results

Sensory panel tests reveal minimal to no differences between the control (fresh beer) and the trial (reconstituted beer)

Continuous concentration process, hygienic design

The Alfa Laval beer and beverage concentration systems feature proprietary filters with an ultra-tight membrane pore structure that allows water to pass easily through while retaining the alcohol, aromas, proteins and sugars in the concentrate. The membrane filters withstand high pressures – enabling higher concentration factors – and eliminate dead zones during Cleaning-in-Place (CIP). This translates into more uptime and higher standards of hygienic design with full membrane cleanability.

Space-saving, energy-saving systems

Choosing Alfa Laval’s reverse osmosis concentration technology results in a space-saving system with significantly lower capital costs and lower energy requirements than other technologies, such as freeze concentration or forward osmosis technologies. Moreover, Alfa Laval beer and beverage concentration systems do not require feed degassing, thereby preventing flavour loss.

Higher throughput, lower costs

Parameter optimization for each beverage maximizes throughput and significantly reduces product losses while retaining the product’s flavour profile.

Alfa Laval Revos applications

Bulk transport

Save €5–15 per hl on tanker transport

Re-draft system

Re-draft cellar: Allow bars to serve beer or other beverages from kegs of concentrate

Re-draft mobile: Provide a compact serving solution for seasonal venues

How it works

Alfa Laval beer and beverage concentration systems use a high-pressure, low-temperature reverse osmosis process. Operating at pressures above 120 bar (1,700 psi) achieves a higher concentration factor, thereby reducing shipping volumes and costs.

To achieve a high-quality concentrate, the product flows through a proprietary membrane filter. The membrane allows water to pass through it, due to pore size and polarity, but prevents the passage of proteins, sugars, aromas and alcohol. Water flows through the membrane, while the pressurized beverage becomes more concentrated as it flows along the membrane.

Teste piloto e locação de sistemas de concentração de cerveja e bebidas

Teste o sistema de concentração Alfa Laval Revos. Envie oito barris de sua cerveja ou bebida para um dos dois locais de teste da Alfa Laval (nos EUA ou na Dinamarca) e participe de um teste no local e avaliação de desempenho.

Você também pode alugar e testar uma unidade em escala comercial para determinar o rendimento do concentrado e a qualidade do produto em seu site.

Perguntas & Respostas - Sistema de concentração Revos

Encontre aqui as respostas para as perguntas mais frequentes sobre o sistema de concentração Revos.

Limitando as emissões de carbono - Saiba mais em nosso white paper

Como as cervejarias e as instalações de fabricação de bebidas podem reduzir suas pegadas de carbono e tornar as operações mais eficientes? A redução de emissões diretas e indiretas desempenha um papel importante – desde a compra de matéria-prima, eletricidade e fabricação até embalagens, materiais e distribuição. Este white paper se concentrará na filtração por membrana de osmose reversa (RO) para concentração de cerveja e bebidas como uma maneira econômica para os fabricantes reduzirem a pegada de carbono de suas cadeias de suprimentos.

Serviços

Serviços do sistema de alimentos

Os serviços de sistema de alimentos da Alfa Laval ajudam a ampliar o desempenho dos seus sistemas de alimentos, maximizando o desempenho dos seus processos. Isso permite que você:

- Melhore continuamente suas operações para manter a vantagem competitiva

- Concentre-se no tempo de atividade, na otimização e na disponibilidade

- Maximize o retorno do investimento ao longo do ciclo de vida dos seus sistemas de alimentos