2023-06-27 Notícias de produtos

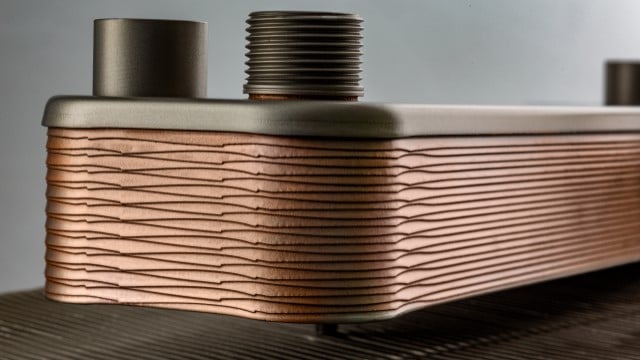

Introducing the Alfa Laval AC900 – a next-generation, single-circuit brazed plate heat exchanger specially designed for low-density, low-GWP refrigerants

At the Net-zero launch event in June 2023, Alfa Laval launched the AC900. It is the newest addition to the growing brazed plate heat exchanger portfolio. With its extra-large gas outlet port, the single-circuit AC900 is optimized for both full and partial-load conditions. It covers capacities between 300 and 600 kW in chillers with screw compressors, industrial chillers, and heat pump applications.

Meeting the needs of a turbulent market

The air conditioning and heating markets are experiencing unprecedented levels of turbulence,” says Malgorzata Moczynska, President, Brazed & Fusion Bonded Heat Exchangers, Energy Division. “Heat pumps are rapidly replacing steam and gas boilers in industrial heating systems. In fact, in the near future we expect the market for high-temperature industrial heat pumps to grow beyond the chiller market, especially in Central Europe, Middle Europe, and the Scandinavian countries.”

A perfect fit for both industrial heat pumps and chillers

“At the same time,” she continues, “new regulations on F-gases have also created – and will continue to create – unexpected challenges for chiller and heat pump manufacturers. Low-density, low-GWP (Global Warming Potential) refrigerants have become standard, forcing many chiller and heat pump manufacturers to redesign their systems”. Alfa Laval has created the AC900, a next-generation, single-circuit brazed plate heat exchanger, especially to meet the challenges in these markets.

An efficient alternative to shell-and-tube heat exchangers

Because the AC900 can manage larger than average capacities, it creates new possibilities in applications where shell-and-tube heat exchangers currently dominate. With its extra-large gas outlet port and DynaStatic distributor system, the AC900 is capable of covering capacities up to 600 kW, and can be custom configured to deliver maximum performance, from partial to full load, in a range of applications.

Saving money and resources

The AC900 is also a great solution for small-to-medium capacity chillers with screw compressors, and for heat pumps and industrial chillers. It requires a much lower refrigerant charge and is more compact, which makes it less expensive to install and also helps save vital steel and copper resources.

The lower installation cost is one part. It is also positive from environmental point of view: the less refrigerant the better.

World-class performance

Recently, the AC900 was tested as a condenser and evaporator at a heat pump manufacturer using a low density refrigerant. The AC900 performed far better than the competition, reaching a new level of thermal performance. “The numbers were quite impressive, and the customer considers the AC900 the absolute best-in-class in this application,” says Roman Rathsack, Senior Global Business Development Manager, Business Unit Brazed & Fusion Bonded Heat Exchangers.

Designed with the environment in mind

Alfa Laval is dedicated to accelerating sustainable solutions in the energy market. With that in mind, the AC900 was designed according to the performance specifications of SEER (Seasonal Energy Efficiency Ratio), defined by the Air Conditioning, Heating and Refrigeration Institute. It also complies with strict new ECO-design requirements defined by The European Environment Agency.

The latest innovation from San Bonifacio, Italy

The AC900, the latest addition to Alfa Laval’s brazed plate heat exchanger portfolio, is also the latest innovation developed and manufactured at Alfa Laval’s state-of-the-art facilities in San Bonifacio, Italy.

Read more about the new product and its key benefits here

Unique features

The Alfa Laval AC900 incorporates several unique features.

- DynaStatic distribution, Alfa Laval’s most recent distribution system, is highly flexible, making it easy to change the geometry inside the distributor. This makes the AC900 adaptable to future trends and future customer needs, including changes in application requirements, new refrigerants, or any other requests.

- IceSafe helps customers prevent and manage freezing in applications with low temperatures.

- ReFuture ensures that the AC900 was designed for optimal performance not only with today’s refrigerants, but with tomorrow’s, making it a future-proof investment that allows customers proactively to address sustainability goals and legislative requirements.

Watch the Net-zero launch event from June 15, 2023

The new Alfa Laval AC900 single-circuit brazed plate heat exchanger was first introduced at Alfa Laval’s Net-zero launch event in June 2023, an online event that introduced new thinking in energy-efficiency, clean energy, and circular-economy solutions. In case you missed it, it’s available here to watch on demand.

For further information, please contact:

Roman Rathsack, Senior Global Business Development Manager

Business Unit Brazed & Fusion bonded Heat Exchangers, Energy Division

Phone: +49 17 13 15 06 91

E-mail: roman.rathsack@alfalaval.com

Therese Tonning, Marketing Communications Manager

Business Unit Brazed & Fusion Bonded Heat Exchangers, Energy Division

Phone: +46 46 36 72 09

E-mail: therese.tonning@alfalaval.com

Alfa Laval brazed plate heat exchangers

Featuring robust construction and innovative design, Alfa Laval’s comprehensive portfolio of brazed plate technology offers an energy efficient alternative to traditional shell-and-tube heat exchangers. The application experience of Alfa Laval’s heating and cooling experts, combined with cutting-edge R&D and manufacturing, ensures you can always access the most competitive solution available. Brazed heat exchangers are ideal for all types of heat pump, air conditioning and process chiller, and commercial and industrial refrigeration applications.

This is Alfa Laval

Alfa Laval is a world leader in heat transfer, centrifugal separation and fluid handling, and is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day.

Alfa Laval has 20,300 employees. Annual sales in 2022 were SEK 52.1 billion (approx. EUR 4.9 billion). The company is listed on Nasdaq Stockholm.

Tags

Tudo Biocombustível Armazenamento de Carbono Ciclo combinado (CHP) Geradores a motor Diesel Energia de combustíveis fósseis Conversão Energia HVAC Refrigeração distrital Refrigerador HVAC Aquecedor HVAC Aquecimento distrital Soluções de ar condicionado e bomba de calor Energia renovável e eficiência energética Energia renovável Energia térmica Maquinário de potência