MBUX

Alfa Laval MBUX industrial centrifuges are designed for recovery of yeast and bacteria in pharmaceutical and probiotics applications. These pharmaceutical centrifuges are available in different sizes and require relatively little energy to recover concentrated solids. The concentrated biomass flows through a set of nozzles into the center of the centrifuge, where it is pumped out under pressure using a paring device. This closed configuration also enhances hygiene.

Experience the benefits of the MBUX , pharmaceutical centrifuges designed for efficient separation of yeast and bacteria

- High uniform concentration of discharged solids phase regardless of fluctuations in feed flow or concentration due to self-regulating vortex nozzles

- Less foaming – light and heavy phase are both discharged under pressure which simplifies installation (no pump systems) and improves hygiene

- No accumulation of packed solids – pockets in the bowl guide solids to the concentrate tubes making separation and CIP easy and effective

- Cost effective operation

- Efficient – bowl can be opened intermittently during production and/or cleaning cycle to eject solids while machine continues to run at full speed

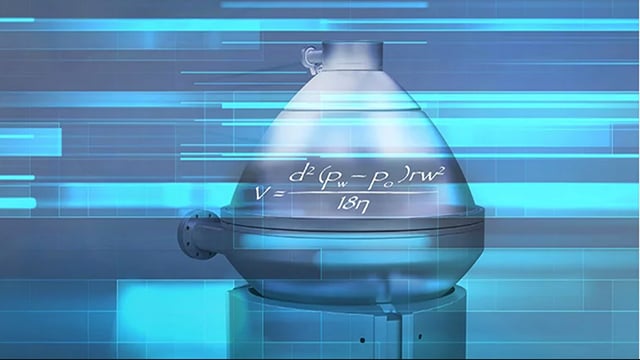

The working principle of MBUX centrifuges

The Alfa Laval MBUX pharmaceutical centrifuges are available in a range of sizes to support diverse processing needs. It is equipped with Alfa Laval’s patented self-regulating vortex nozzles, which maintain a consistent discharge solids concentration—even when feed flow or solids content changes.

These nozzle separators operate based on the fluid’s viscosity and the rotational speed inside the vortex chamber, which together determine the pressure drop. The concentrate enters the nozzle chamber tangentially, creating a centrifugal whirl that exits through a central outlet. While the pressure drop at the inlet and outlet is mostly unaffected by viscosity, the pressure drop created by the internal vortex increases or decreases with the rotation speed.

Thanks to this design, the solids concentration remains consistently high. This allows the pharmaceutical centrifuge to operate closer to its clogging limit while still minimizing the risk of blockage. It offers a clear advantage over traditional yeast centrifuge systems, especially when handling shear-sensitive materials or variable feed compositions.

The light and heavy phases are both discharged under pressure, which helps prevent foaming, makes installation easier by removing the need for pumps, and improves hygiene. Solids collect in pockets in the bowl and are directed to the concentrate tubes. This prevents solids from building up tightly and makes separation and Cleaning-in-Place (CIP) easier and more effective.

Standard design

All parts in contact with liquid are made of high-grade stainless steel. The bowl body is made of Super Duplex stainless steel. Rubber seals are made of food-approved EPDM or nitrile rubber. The yeast separator includes speed and vibration sensors. The anchoring feet have vibration dampers. The MBUX separator is powered by a flange-mounted motor, which comes pre-mounted from the factory—so no alignment is needed on site.

Automated CIP at full speed

The bowl can be opened at intervals during production or cleaning to eject solids, while the machine keeps running at full speed. The frame hood has a spray nozzle for cleaning the outside of the bowl.

Service

Extending the performance of your equipment

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

Separation expertise for next-generation food

The food landscape is changing, through groundbreaking research and cutting-edge technology. Alfa Laval provides unmatched separation expertise for this transformation: bringing scalability, profitability, and resource efficiency to next-generation food processes, like cellular agriculture.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.